You Need Custom Tees, Now What?

SCREEN PRINTING

$ | Fast Turnaround

What is Screen Printing?

Screen printing is the process behind most of the t-shirts you see today. Invented in China when they discovered that holding a silk mesh over a wooden frame with strategically placed holes left an awesome design on the fabric. It quickly spread to other countries and the technique was improved into the beloved screen printing we know today. Screen printing basically pastes a layer of colour on top of the garment through a screen. This is a multi-step process that involves placing different screens over a shirt in perfect alignment to create the final design with each colour using a different screen.

Pros

Simple & versatile. A very durable technique that is easily scalable, silk screening is your best option for simple designs with few colours. Silk screening works with almost all fabric types and has a fairly smooth finish.

Cons

Limited colour mixing as the ink is pushed through the screens, the resolution of the design is also limited meaning realistic images and shading is limited. The end result is not stretchable and will eventually crack.

Suggested Use:

At least 50 to 1,000+ articles of clothing, dark or light fabric, long term use. Team uniforms, event shirts, trade show giveaways, branding.

DTG (DIRECT TO GARMENT)

$$$$ | Very Fast Turnaround

What is DTG?

This is a relatively new technique that was started in the 90’s by a digital image company and it became commercially available in 2005. This technique took the printing world by storm. As the name states, this technique prints ink directly into the garments. This technique goes straight into the fibre meaning that on white fabrics you don’t feel the ink when you touch the t-shirts.

Pros

Extensive colour options and maximum detail in design, easily customizable designs, every shirt can be different or unique to its wearer.

Cons

Not cost effective for big batches. Limited design placement. Dark garments are prone to cracking after repeated washings. Best for cottons and some cotton mixes.

Suggested Use:

1-20 articles of clothing, dark or light fabric, short term use. Photographic images.

One off unique clothing such as wedding shirts where each shirt follows a common theme but may have different messages.

TRANSFER PRINTING

$$ | Slow Turnaround

What is Transfer Printing?

Originally the method behind this technique is that it transfers an image from one surface to another, permanently. It was mostly used to add decorative details and features to ceramics. The process has now been applied to transfer designs onto t-shirts and other types of garments. You can distinguish transfer printing from other printing techniques because it requires heat to be applied at the end to set the image.

Pros

Fairly simple and it can produce high quality, complex designs.

Cons

Slower than the other methods. Limited fabrics it can be printed on, as it can’t be used on fabrics sensitive to high temperatures. Not stretchable.

Suggested Use:

10-50 articles of clothing, dark or light fabric, short term use.

ElastXNEW!

$ | Extremely Fast Turnaround*

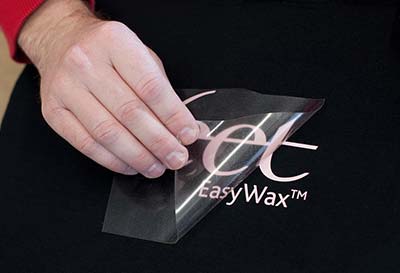

What is ElastX?

Very new to the market, this product may be a game changer and as of this writing we are one of the few companies offering this in North America. Images are printed on a press allowing for extremely fine detail, then a white opaque backer is applied to the back of the image as well as a fabric safe heat activated adhesive. Like Heat Transfers above, these are applied with a heat press but due to their process they are easier to apply and do not require a lot of heat to activate the glue. This allows ElastX to be applied to a larger range of fabrics. Learn More!

*The ElastX process has some original setup costs, but hundreds of your design can be produced at one time and applied to garments in mere minutes at a later time.

Pros

High quality images, applies to dark or light fabrics, very nice soft feel, extremely durable and stretchy.

Cons

Does not handle stand alone thin design elements well.

Suggested Use:

20 – 500 articles of clothing, dark or light fabric, long term use, large and small designs, team uniforms, company uniforms, charity events, branding.

CAD CUT VINYL

$ | Fast Turnaround

What is CAD Cut Vinyl?

Even though it is considered a printing technique there is no printing involved. A machine cuts a high quality vinyl paper into the shape of the design. One of the most common uses for this technique is the sports kit. This is heavily used for jersey numbering and block lettered names.

Pros

No setup costs and gives bold and vibrant colour images, can also be used on polyester and nylon

Cons

Not suitable for oversized designs, very little detail, thick plastic feel.

Suggested Use:

1-25 articles of clothing, dark or light fabric, long term use, Jerseys, team numbers.

EMBROIDERY

$$$ | Slow Turnaround

What is Embroidery?

Embroidery does not involve printing instead a machine stitches a particular design or text onto the garment of choice. It is one of the most used methods for polo/golf shirts and corporate work wear. Embroidery is the go-to method for producing hats; however, depending on the style, heat transfers and ElastX may be used as well.

Pros

Very professional looking, long term use.

Cons

Logos may have to be altered as small text and design elements or shading can be difficult to show with thread.

Get Your Custom Apparel

Request a custom Quote

[caldera_form id=”CF5ae34ab38ee11″]